We have compiled, in one place, all of the information needed to help you make your decision when selecting fiberglass preformed shapes. This Pultruded Fiberglass Information and Resources page, also known as our “Max-Tips” page, will be updated with any information we are told by customers and verify that they do indeed work.

Quick Jump Links

Joining / Connecting Cutting Drilling Bonding & Adhesives Painting Sleeving ReinforcementSample Packs

Joining / Connecting Fiberglass Sections

Method One: Slotting

One method is to cut a slot in the end of the larger of the two tubes using a hacksaw. The slot should be about 2 inches long, and well centered in the tube. You may then use an all-stainless hose clamp (also called a screw clamp) to fit over the outside of the larger tube and compress the portion with the slot around the smaller tube inside, holding it firmly. This method has the advantage of being easily removable for disassembly if required. A second screw clamp may be used for greater security at the joint.

Method Two: Gluing

A second method is to glue the tubes together. You may use epoxy (the 50/50 type….consistency of syrup….not the “filler” types of epoxy which are the consistency of putty.) Note that epoxy adhesives do not want to bend or flex. They get quite rigid, so if you are using the fiberglass in an application where the joint will be subject to bending, epoxy is NOT the best choice. If you have adequate curing time, adhesives such as “Goop” (or the very similar and cheaper “clear elastomeric caulk” ) are sold in paint departments of many stores with the caulking products. A caulking-gun sized tube is usually around $5, and will do a large number of tubes.

The best adhesive to use is JB-Weld, 2 part epoxy, “Originial Cold Weld Formula”. This adhesive sets in 30 minutes and cures in 4 hours, ready to use in 24 hours. This adhesive comes in two tubes colored red and black (in either 1oz tubes OR the bigger 5oz tubes). When the two are properly mixed together the mixture will turn a medium gray color. Do not apply until you fully mix the adhesive. This adhesive is sold in most hardware stores and also in the paint department. Usually sold in a blister pack that has a red coloration.

A good method of applying all of these adhesives inside tubes is to squirt the adhesive on a dowel or rod of a smaller diameter than the inside of the tube to be glued. Roll the dowel around on the inside of the larger tube, evenly spreading the adhesive on the inside wall. This is easily done from both ends of the tube. As soon as adhesive is spread, slide the smaller tube or rod you wish to secure inside the larger tube and allow to cure. Be sure the tube is not bent when curing, or it will set in that form!

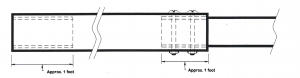

Method Three: Pinning

The third method is by use of a couple of stainless machine screws which go through both tubes. An illustration of this method is below:

When drilling holes for the machine screws to hold sections together, assemble the spreader joint with the exact overlap in place, and drill all the way through both sides at once (taking care to drill straight through the centerline of the tube, perpendicular to its surface.) This method also allows for disassembly if desired. For additional security, apply a little thread lock or glue to the nuts after tightening.

Method Four: Connectors and Adapters

The fourth method would be to use a connector, adapter, clamp, ferrule, or coupler that we have already purpose built to work with our fiberglass tube and rod. See all of the options available here.

Cutting

Cutting our fiberglass yourself, here are a few helpful notes:

A fine-toothed hacksaw will do the job on very small quantity jobs. Be certain to support the back side of the tube / rod when cutting through to avoid splintering of the fiberglass as the blade comes through the back. Rest the fiberglass on a piece of scrap wood at the point of the cut. A wrap of masking tape at the cut point also helps. Also support the piece of fiberglass level with the cut all along its length. You do not want the ends to fall down as the cut nears completion, splintering the last few strands of fiberglass on the back side of the cut. Another technique which works well if cutting solid rods and the diameter is large enough is to apply masking tape around the rod at the cut point, mark the cut line evenly all the way around the rod on the tape, then saw completely around the cut line, rolling the rod as you cut. This cuts all the surface glass strands nicely, and lets you complete the cut toward the center of the rod, not coming out the back side, avoiding surface splintering.

Do not breathe the fiberglass dust. It is a good idea to cut outdoors. Use a good protective mask and eye protection.

If you have the equipment, a far better cutting method is by use of a power miter saw or “chop saw” with an abrasive blade. These tools will give you a perfect, square, smooth cut every time. NEVER use a toothed blade. The finer the abrasive on the abrasive cutting blade, the nicer the resulting cut, but the cut will also take longer than with coarser blades. Even the very common (and cheap) “metal cutting” or ceramic / concrete cutting abrasive blades that fit these tools will work fine, and they are commonly available at Home Depot and other home improvement and hardware stores.

FAQ:

1.) How can I void “splintering” the fiberglass when cutting?

Answer: There are a couple ways. The easiest way is to wrap the area to be cut with masking tape before the cut is made. With the masking tape on the fiberglass you can easily write notes on the tape to make your cut easier as well. For example, if you need to cut a 17 inch piece, measure 17 inches out from the end of the rod. Make your mark at 17 inches. Draw an “arrow” on the side opposite of the 17 inch piece needed. This will tell you which side of the line to position your cutting blade. If you cut in the middle of the line, the saw kerf will shave of a little of the approximate 17 inch piece needed.

In all cases, use care when cutting, use breathing protection, and cut outdoors where possible. If you are not knowledgeable in the use of these types of tools, seek professional help / advice, or leave it to the pros!

On shipments from our retail warehouse, there is a cutting charge of $2.50 per cut. If we can bundle several pieces of your order together and cut them all at one time (such as when 20 pieces of small diameter rod which is all being cut to the same length) and this still just counts as one cut, and the charge is only $2.50. The number we can bundle for a single cut depends, of course, on the diameter and type of product ordered, but we will always do our best to save you money on the cuts .

*****On wholesale / OEM quantity orders ($400 minimum order) of round tube and round solid rod that we can ship direct from our factory, there is NO CHARGE for cutting.

Tolerances: At our retail warehouse, we do “rough cuts” only, with best tolerance of 1/8 inch. At the factory we have far more elaborate diamond saws, and can easily cut to tolerances of 1/16 inch at no extra charge. Tighter tolerances ARE possible from the factory, but usually carry additional charges. (Inquire) Let us quote on your needs!

Drilling

When drilling through fiberglass preformed shapes you need to be sure you have the right tools. Drill bits that are carbide tipped are the best choice. Fiberglass is VERY abrasive and will dull other bits very quickly. Be sure to use the fastest speed setting on your drill.

If you have a sharp bit you will not need to apply much pressure behind the drill. If you apply too much pressure to the drill, and don’t allow the drill bit to slowly eat through the fiberglass, you will “punch” through the back side of the fiberglass. This will cause surface strand splintering at the exit site. A wrap of masking tape at the drilling location is helpful in avoiding exit hole splintering. If you are drilling hollow tubes, drill through the first side, then very slowly start to drill the interior of the tube on the exit side of the hole. When you first detect penetration of the back surface by the drill bit, you can rotate the tube and using the point of detectable penetration as a location guide, finish drilling the exit hole from the outside as opposed to punching completely through from the inside. This method is more time consuming, but is excellent to get clean exit holes.

Drilling Article and Video

Bonding and Adhesives

When bonding fiberglass surfaces you need to prepare the surface. Wipe down the surface with a DAMP CLOTH only! DO NOT wipe it down with solvents or other chemicals. Methel Ethel Ketone (M.E.K) can be used to remove “goo” from the surface. Allow the surface to dry then wipe down with a damp cloth again to remove any residual residue.

Smooth surfaces need to be “roughed up” so the adhesive has more ridges to adhere to. Use a sanding wheel, OR coarse grit sand paper by hand, to rough up only the surface to be bonded.

Adhesives to use:

Epoxies, Methacrylate, Urethane. For a hard, tough, rigid bond JB Weld (Original Cold Weld Formula) 2 part, hand mix epoxy, is a prolific, fast setting option. great at keeping sleeved tubes and rods held together, keeping other items attached to the ends of the fiberglass, and general joining.

Ashland Pliogrip Urethane Adhesive is a construction adhesive that is available for industrial applications, but is THE BEST to adhering fiberglass together and other parts onto fiberglass that WE know of. NOTE! This product requires a special application tool. Becomes very economical for large use applications.

DO NOT use super glues (crazy glue) cyanoacrylate, expanding adhesives, wood glues OR PVC glues. All of these will not work. Super glues (cyanoacrylate) will become a hard as a rock and either become brittle over time and flake away or the bonding surface will loosen. Expanding glues like the famous “Gorilla Glue” will work if used to bond two pieces together and you do not need the tubes or rods to sleeve OR care about how the project looks. Expanding glues, when applied, go EVERYWHERE. It squeezes out of and into every hole available. If using on parts that are to be sleeved together, get ready for internal complications. Wood glues are self explanatory. They adhere to wood and not fiberglass. The wood glue will pool on the surface of the fiberglass and never adhere. They just don’t work. PVC glues work by chemically melting the PVC parts. Fiberglass, not being PVC, is totally unaffected by these chemicals and the PVC glues will simply drip off.

When an adhesive are applied be sure to set your work in a place for the adhesive to cure in it’s final place. If you apply an adhesive that is in a “goopy” state then set the work down somewhere without clamps or support, you might come back and your work could have slid apart and set not where you desired.

If there is extra adhesive squirting out from between the pieces you are bonding, use your finger or plastic piece to wipe of excess and form a nice “bead” along the seam.

Painting

Surface prep:

When painting fiberglass there is minimal surface prep required. Wipe the bare surface of the fiberglass with a damp towel only to remove any surface dust. DO NOT use solvents as it will impede the paint from adhering to the fiberglass. If there are surface contaminants on the fiberglass, use Methol Ethel Ketone (M.E.K.) to wipe the surface clean, allow to dry completely, then wipe off the surface with a damp cloth again.

DO NOT paint surfaces that are to be “sleeved” inside other tubes. Sleeving fiberglass was designed with particular tolerances in mind. Applying a paint layer will take away these thousandths that are required for a smooth sleeve.

Applying the paint:

Start by giving the fiberglass a good coat of a spray primer. Our favorite is Rustoleum 2X Ultra Cover Flat Gray Primer, which bonds to plastics. Allow 48 hours cure time before top coating. When the primer is set and dry apply at least two coats of the same brand (rustoleum) Flat Black Spray Paint.

Low visibility applications:

The best paint to use for low visibility is a matte finish black spray paint. Flat Black almost seems to make antennas disappear, especially when viewed against a background such as trees.

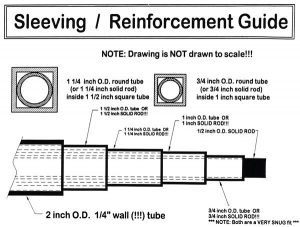

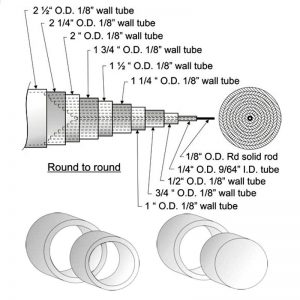

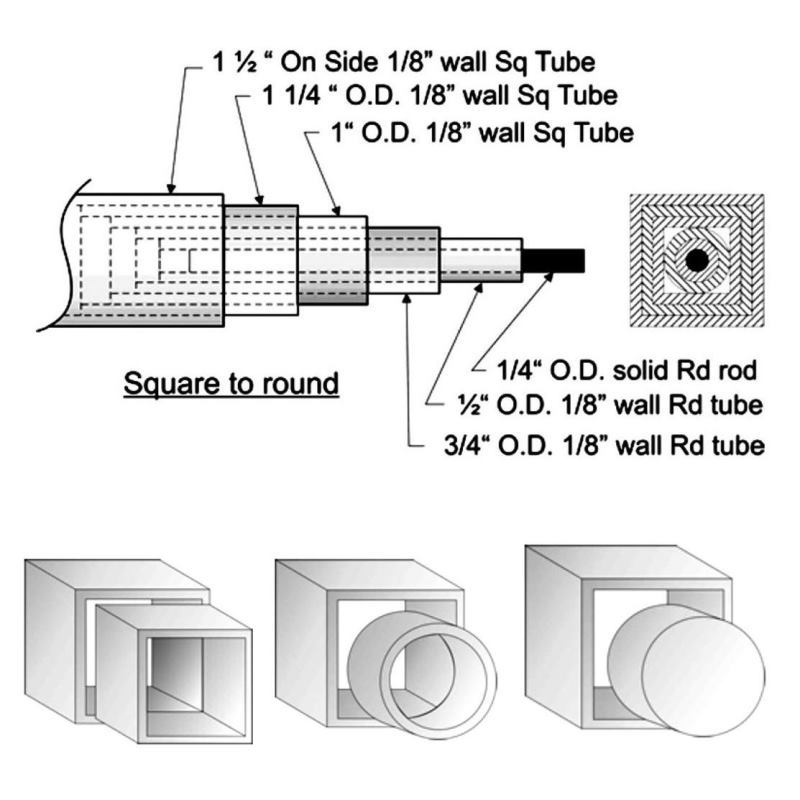

Fiberglass Sleeving / Reinforcement Guide

We offer sample packs which include one piece each of our corresponding fiberglass tube and rod. Working on a project and don’t know which tube will do the job? These packs are ideal to examine fit, finish, mechanical properties, etc. on a variety of our products. Included are either approximately 6 inch long pieces or 23 inch long pieces of the desired fiberglass products as detailed and shown below:

P/N: RT-SPL

Round Tube Sleeving Sample Packs

P/N: RT-SPL-QTR

Round Tube 1/4″ Wall Sample Packs

P/N: ST-SPL

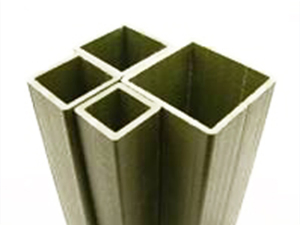

Square Tube Sample Packs

P/N: RSR-SPL

Round Solid Rod Sample Packs

Please note: The sleeving and reinforcement guide below is for Max-Gain Systems’ proprietary line of tube and rod only. All sizes are “nominal” and allow a few thousandths for sleeving purposes.

These same stated sizes of tube and rod from other manufacturers probably will NOT mate with our line!

|

Round Tube

|

||

|

Tubing Size

|

Accepted Inside Sizes

|

Accepted Outside Sizes

|

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

Note: Our square tube to square tube sleeving combinations, while perfect for reinforcement or extension applications, will be too snug for full-length slip-fit applications, such as push-up masts. Our square tube will only sleeve 6-12 inches. The square tube to round tube mating combinations will yield less strength at the joint (due to only 4 point contact) than either round-to-round or square-to-square combinations.

|

Square Tube

|

||

|

Tubing Size

|

Accepted Inside Sizes

|

Accepted Outside Sizes

|

| 1.25″ on-side X 1/8″ wall square tube (snug fit) | ||

| 1.5″ on-side X 1/8″ wall square tube (snug fit) | ||

| 1.75″ on-side X 1/8″ wall square tube (snug fit) 2″ on-side X 1/4″ wall square tube (snug fit) |

||

| 2″ on-side X 1/8″ wall square tube (snug fit) | ||

| No direct available sizes | ||

| No direct available sizes | ||

|

Round Solid Rod

|

||

|

Rod Size

|

Accepted Outside Sizes / Sleeves Into

|

|

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||

|

no direct sizes

|

||