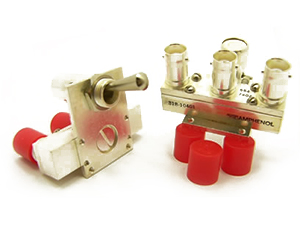

UHF male Solder Connector for RG-8, RG-11, RG-83, RG-213, RG-393, LMR-400, and other 0.405 Inch OD Coax, PL-259 Solder On Connector

Silver Plated Brass Body

Silver Plated Brass Center Pin

PTFE Dielectric

“TSS”

Detailed Product Information

Description

This UHF male Solder Connector is one of several thousand RF products available from Max-Gain Systems, Inc.

This connector is made from a Solid Brass body that is precision machined and plated with Silver for superior performance and value. This UHF male Solder Connector has a PTFE dielectric and a silver plated brass center pin. The UHF male interface (also known as a PL-259 connection) is by far the most popular connection type used in Amateur Radio.

Our PL-259 connectors are the best on the market. They can take the heat, wont fall apart when soldering, AND take more power than any PL-259 connectors on the market. These PL-259 connectors represent the peak in connector design.

7500-UHF, 7500-UHF-400, 7500-400, PL-259, UHF Male

Compatible with Coaxial Cable Types: RG-8, RG-11, RG-83, RG-213, RG-393, LMR-400, Belden 8237, Belden 8267, Belden 9011, Belden 9913 and other 0.390 and 0.400 inch OD Coaxial cable.

Proof of design and materials:

See our internal testing below by playing the video. NOTE: Do not use a blow torch (demonstration only) on the PL-259 as shown as you will not solder the connector that way and you may melt your coax, but the PL-259 connector can take the heat.

Our PL-259 connectors are made from machined solid brass bodies, PTFE dielectric, machined solid brass center pin, and finally, a thick coating of silver for the best connection and soldering capability possible!

Installation Guide:

We will begin by installing the PL-259 connector on a piece of LMR-400. This process is the same for all the other types of cable that fit the PL-259 connector. These connectors fit on a wide range of coax types including, but not limited to: RG-8, RG-11, RG-83, RG-213, RG-393, LMR-400, Belden 8237, Belden 8267, Belden 9011, and Belden 9913. For smaller coax sizes a reducer will need to be used. See the 7508-S for RG-8X, RG-59, RG-6, RG-62, RG-223, LMR-240, Belden 7916A, Belden 8241, and Belden 9258. See 7507-S for RG-58, RG-58A/U, RG-142, RG-400, LMR-195, LMR-200, Belden 9201, Belden 8219, Belden 8259, and Belden 7807. See 7506-S for RG-174, RG-178, RG-188, RG-196, LMR-100A, LMR-100, LMR-110, and Belden 8216.

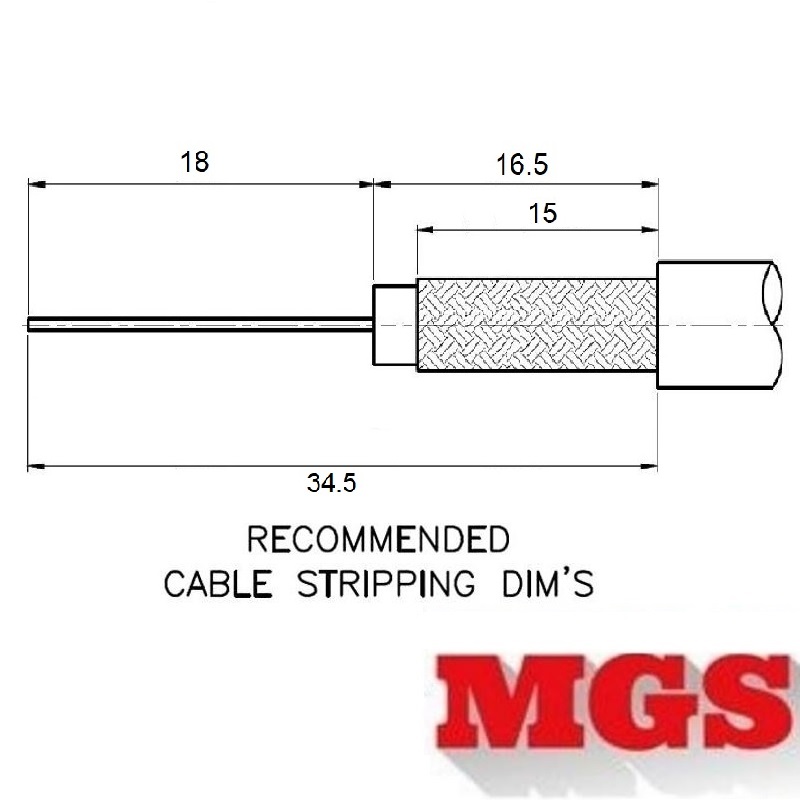

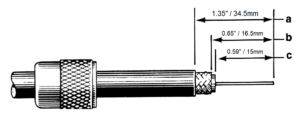

Coax Stripping:

First cut your cable to the desired length and then strip the black jacket back approximately 1 inch. When the jacket is stripped cut the braid/foil back 0.75 of an inch from the fresh cut end. Finally, cut back the dielectric 0.6875 of an inch from the fresh end down to the center conductor. The braid needs to be cut back further than the dielectric to insure that none of the braid or foil is touching the center conductor which could cause a short.

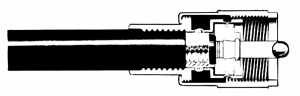

Once the cable is prepped, make sure to put the sleeve of the PL-259 on the cable before you put the body of the PL-259 on the cable, with the knurled end of the sleeve closest to the tip of the connector.

Main Body Install:

Put the PL-259 main body on the end of the cable and grip it with a pair of pliers and begin screwing it to the right (clockwise) till the center conductor is flush with the tip end of the center pin of the PL-259 connector itself.

FAQ #1: Why wont the center conductor go into the connector?

Answer 1: The center is bent off of center. Ensure the center conductor is perfectly straight before screwing the connector body onto the coax.

Answer 2: The tip of the center conductor was flattened by diagonal cutters when cutting the coax. To fix this, use a pair of pliers to round back out the tip of the center conductor.

Answer 3: The strands spread apart making the center conductor too large. LMR-400 coax is available in solid core and stranded versions. When cut, the strands of the stranded version can “loosen” and come separated. You will need to re-tighten the strands by twisting them back to their original diameter.

Soldering Guide:

This soldering guide is for soldering Max-Gain Systems, Inc. PL-259 connectors. These are approximate measurements for our PL-259 connectors, which adhere to industry standards for this type connector. If you choose to use this guide for connectors sold by others who do NOT adhere to these standards, the measurements could be off and result in a poor installation.

Now we begin soldering the PL-259 connector to the cable. Begin by applying heat to the center pin of the PL-259 connector with your soldering iron. Before proceeding, allow sufficient time for the soldering iron tip to reach full operating temperature and clean the tip of the iron by wiping it with a damp sponge. Be sure the soldering iron is on the bottom side of the center pin. The heat rises and heats up the pin faster. When the pin is heated, apply the solder to the tip of the center conductor. Allow sufficient solder to flow to seal the center conductor inside the center pin.

Once the center pin is sealed with solder, move the soldering iron to the holes of the PL-259. Make sure to fill all four of the holes with solder flush with the top of each hole. Once all four holes of the PL-259 are filled with solder let the connector cool down. When the connector is cool take the sleeve (which should have been put on the cable before the PL-259 was screwed on the cable) and slide it up the cable onto the connector and screw it up into place.

Final Testing:

When this is completed, as a final test, you should always check resistance from the center pin to the body with an ohmmeter in a low resistance scale. After verifying that there are no braid – to – center pin shorts on the other end of the coaxial cable, you should see infinite resistance (open).

As a final check, inspect the tip of the center pin to be certain that there is no excess solder present. This could interfere with easy insertion of the tip of the PL-259 into the female (SO-239) connector. If there is a tiny bit of excess solder present, it can usually be easily removed. Lightly scrape the soft solder with the edge of a knife blade until smooth. This completes your PL-259 installation, and the connector is ready for use!

See our entire line RF Connectors and Adapters:

About Max-Gain Systems, Inc.

Max-Gain Systems, Inc. carries a full line of in-series, between series, right angle, T-shaped, quick connect, handie-talkie (BLACK), pigtails (coaxial jumpers), etc… RF adapters. Our RF adapter lines are constantly expanding. We keep our RF connector and adapter lines in stock. We ship both retail and wholesale quantities. To become a dealer / wholesale user, contact us with your potential usage. PL-259 Solder On Connector

Max-Gain Systems, Inc. is the number one supplier of fiberglass round hollow tube, square tube and round solid rod to the antenna manufacturing industry. We produce millions of feet a year for hundreds of different industries including but not limited to: marine / boating, aeronautical, agriculture, construction, emergency services, etc…. We have the unique ability to sell one piece or even a semi-truck full. Feel free to prototype using our fiberglass tube and rod then contact us for a quote on a production run. At production run quantities we can cut to your desired lengths at no additional charge, and we can also perform several different fabrications (example: drilling holes in precise locations along a tube) to ensure your delivered material is ready for assembly. We have several accessory items designed for our fiberglass including but not limited to: couplers, telescoping clamps, ferrules, etc…