In this article we will be going in depth about drilling holes into fiberglass tube and rod. There are many useful tips and tricks to know in advance, in order to have the best success. No one likes blown out holes or splinters everywhere and these tips and tricks will help to mitigate that.

Fiberglass Tube and Rod

We sell a wide variety of diameters and lengths of fiberglass tube and rod. From as small as 5/64″ and up to 2.5″ in outer diameter. With many sizes to choose from, you can design almost anything with it.

See a complete list of all of our fiberglass tubes and rods, here:

Preparation

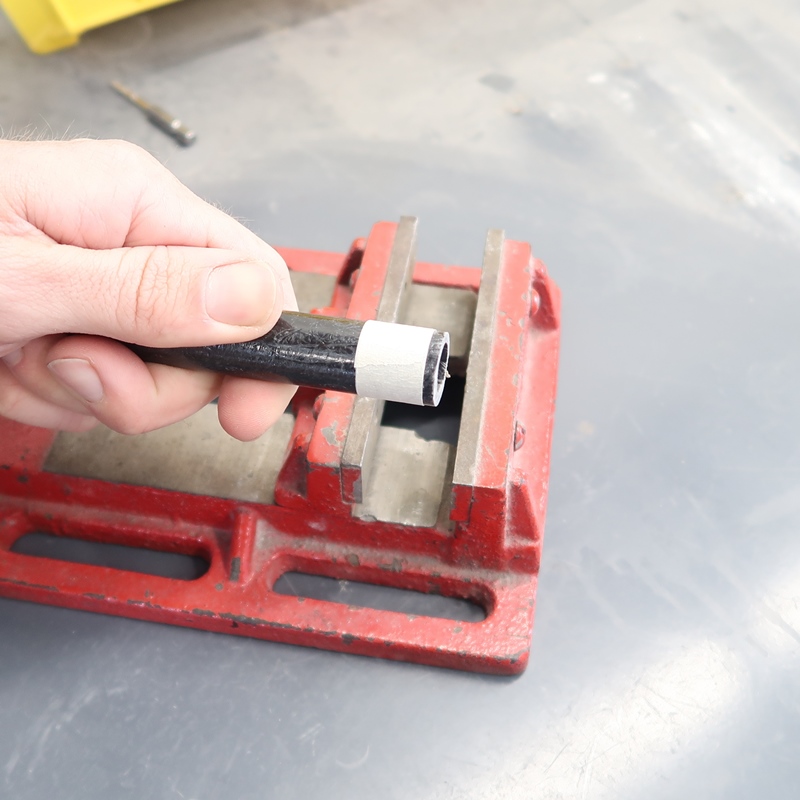

To have the best success in drilling through fiberglass, a little prep work will greatly aid in the desired result. Determine where along the tube or rod you are looking to drill your hole. Wrap the tube with masking tape. Give it about three wraps. Try to get those wraps tight in order to provide inward pressure on the exterior of the tube or rod. This will assist in mitigating fraying, splintering, and punch outs. Once wrapped, if you would like to, you can take the point of a sharp knife and rotate it at the point you are looking to start your drilled hole. This will provide a stable starting spot for your drill bit to in order to stop “drill walking” where the drill bit could otherwise rotate right off of the material.

Pilot Hole

If you are looking to drill a large hole through the fiberglass, it is good practice to drill a pilot hole first. I like to use a 7/64 inch drill bit for my pilot hole as this helps to mitigate drill bit walking when drilling a larger hole. Set your drill to it’s fastest drilling speed and begin drilling without applying additional pressure to the hole to be drilled. Light pressure, usually the weight of the drill is plenty, will allow the drill bit to eat away at the material and avoid the dreaded punch out from the backside. Allowing the drill bit to eat away as little of the material as possible, per rotation, will allow for a cleaner hole and mitigate punch out.

Drilling a Large Hole

Change out your pilot bit for the larger bit. place the bit on the same hole then begin to drill on the fastest speed your drill has. In order to get the cleanest hole try to regulate the pressure that the drill applies to the tube. With a very aggressive drill bit, even the pressure of just the drill bit, can cause the drill to rush through the material which could result in a less clean hole. We are nitpicking here, but our goal is a nice clean hole.

Clean Up

Once you finish your drilled hole, you can now blow out the dust (don’t breathe the dust) and peal off the tape. If there are loose fibers, you can clean it up by using a pair of small, sharp diagonal cutters.

More tips!

See more tips and trick for fabricating fiberglass tube and rod on our “Max-Tips” page here: