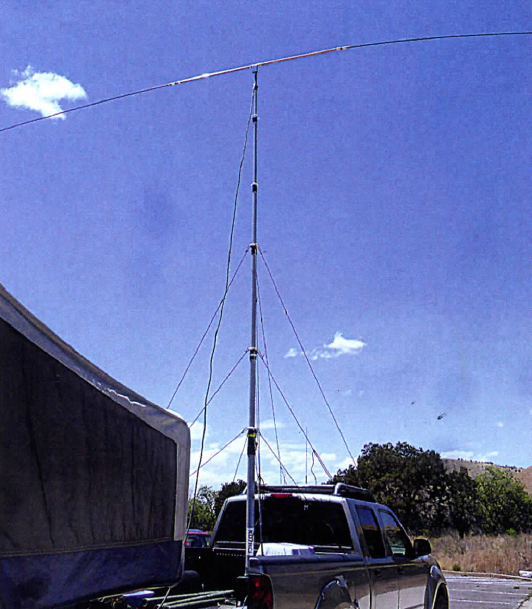

Max-Gain Systems carries a full line of flip lever telescopic fiberglass tubing. It was only fitting that we engineer a way to connect each corresponding size. We did, and in a way that is simple, fluid, and durable. The “Quik-Clamp” flip lever telescoping tube clamps are the perfect solution.

These “Quik-Clamps” are made of a durable polycarbonate material. This material holds its shape and retains its springiness even after years of use. These can easily withstand temperature extremes of any environment you might throw at it. We have customer reports of these in use in the dessert AND in the arctic (at a research laboratory). These were designed to be used with our fiberglass telescoping tube with 1/8 inch wall thickness. These clamps are also RF transparent like our fiberglass tubes. Use a #3 phillips screw driver. Be sure the screw driver is fully seated inside the screw before tightening the clamps. A smaller phillips screw driver could strip this screw threads.

The screws for the clamps are Stainless Steel. Extremely durable and corrosion resistant.

Installation

Glues and Adhesives

Surface Prep: Do not clean the fiberglass surface with alcohol, mineral spirits, etc… if you wish to clean the surface, use ONLY a damp towel to wipe off surface dust.

JB Weld 2 Part Epoxy (The Original Coldweld Formula). A standard package (1 oz) from the hardware store should do the trick. Squeeze out some of the hardener onto a surface you will throw away afterwards. I used a cut off piece box I had around. Then, on top of the hardener, squeeze an equal amount of the resin. Be sure to have paper towels at the ready at this stage. JB Weld starts to set quickly and you will need to be sure you do not drip any of this on to any unwanted area. Mix the JB Weld up by swirling it and folding from the outside of the pile inward. Once the black and white parts are mixed it should turn completely gray.

Applying the Adhesive

The adhesive does not need to be smeared all over the tube. We are going to make one thick bead of adhesive, one inch down, from one end of the tube. When the thick bead is done being applied to the tube, place the corresponding telescoping tube clamp onto the tube. Rotate the clamp a quarter turn, left and right, while slowly pressing the clamp onto the tube. This will smear the adhesive around plenty and this also avoids the largest potential problem of adhesive migrating its way up the tube and squeezing its way over the edge of the tube and inside the clamping area. This would make an impassible block of adhesive. Following these directions will completely avoid that. Right now the adhesive is still a little runny so be sure to set the tube down on a flat surface AND, before you let go of the tube and clamp, make sure the telescoping tube clamp is completely seated. If not, this could create a “binding point” because the clamp would not be aligned.

Glues “NOT” to use:

Glues which expand as they dry, such as “Gorilla Glue” are NOT recommended, because the glue tends to migrate into places where it should not be as it expands. Do NOT use PVC cement (purple and clear mixture), which works by dissolving PVC and “melting” it together. It will NOT dissolve fiberglass and will not work at all. Do NOT use Liquid Nails or any other glue designed for gluing wood. These glues will not bond to fiberglass and will only make a mess. Do NOT use “Super Glues”. They cure then become rock hard and brittle.

Clamp Operation

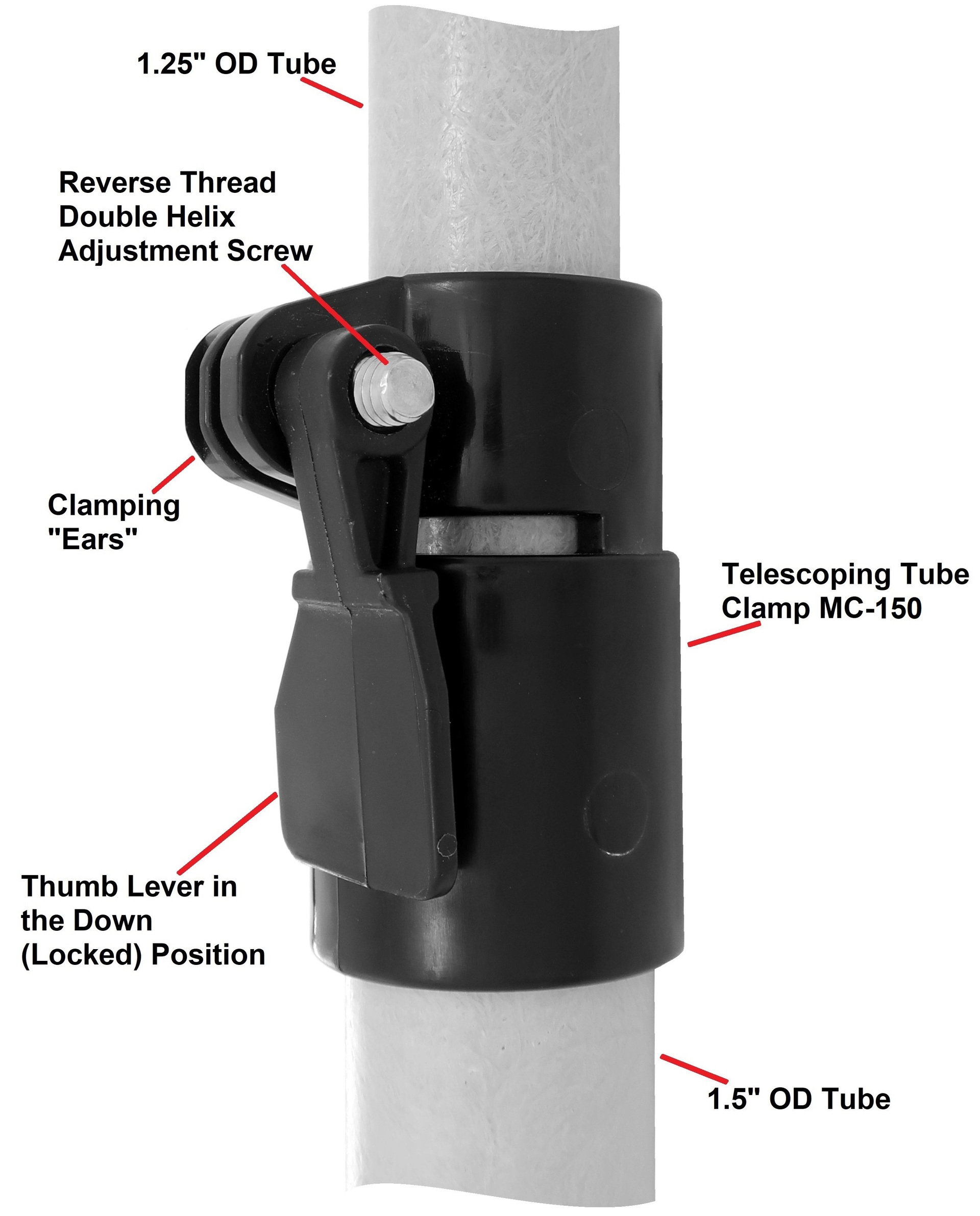

After the Quik-Clamps are cured, you can then raise the thumb-clamp levers and insert the tubes within one another. You will notice a screw in the clamp. This screw is used to adjust the tension of the clamping mechanism. With a Phillips head screwdriver, (be certain to use a large enough Phillips screwdriver to properly engage the large screw slots. (Preferably a #3 Phillips). Tighten the screw just to the point before it hinders passage of the inner tube. The screw is REVERSE THREAD, so turn COUNTERCLOCKWISE to tighten. TEST the thumb clamp at that point, and make certain that you have the tension adjusted properly so that you may extend the inner tube, and that when the thumb clamp is in the “down” position, that the inner tube is gripped FIRMLY. It is important to not over-tighten the screw. The thumb clamps have tremendous leverage, and if over-tightened, something HAS to give… (probably one of the sides of the clamp “ears”). Try this adjustment a few times until you find the perfect setting. Do not use thread-lock compound on the screws. It is not necessary, and thread-lock compound is one of the very few things that can attack and weaken the material used to make the clamps.

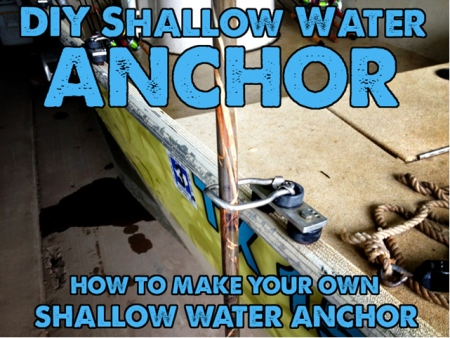

These clamps, in combination with our fiberglass telescoping tube, can support any number of different items for an unlimited amount of uses

2.50 inch ID Clamp will fit on the end of our 2.5 inch OD x 1/8 WALL, Round Tube and clamp on to our 2.25 inch OD Round Tube, Part Number MC-250 (9190)

2.25 inch ID Clamp will fit on the end of our 2.25 inch OD x 1/8 WALL, Round Tube and clamp on to our 2 inch OD Round Tube, Part Number MC-225 (9185)

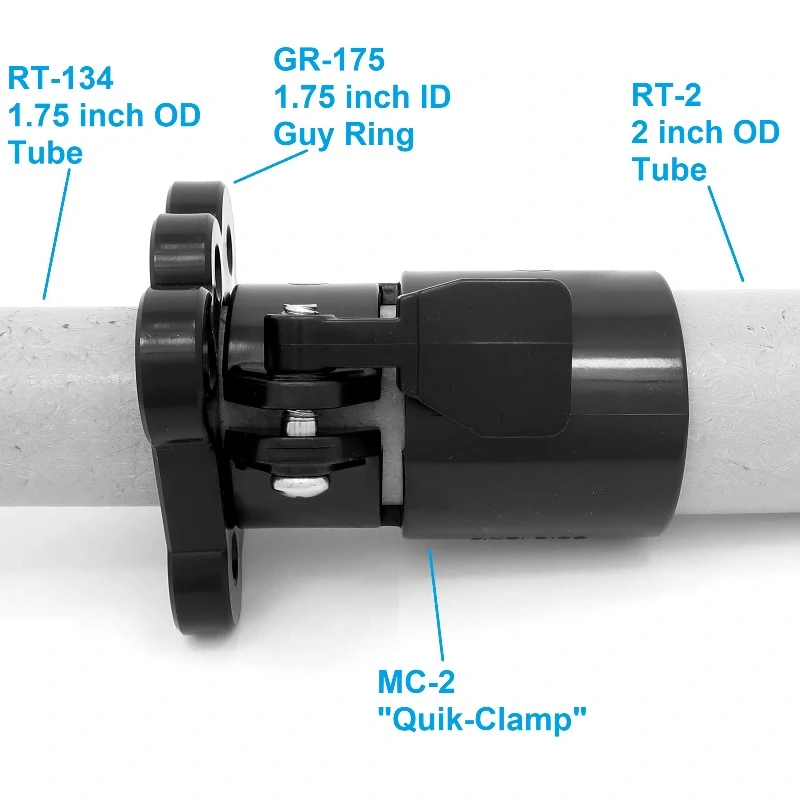

2 inch ID Clamp will fit on the end of our 2 inch OD x 1/8 WALL, Round Tube and clamp on to our 1.75 inch OD Round Tube, Part Number MC-2 (9180)

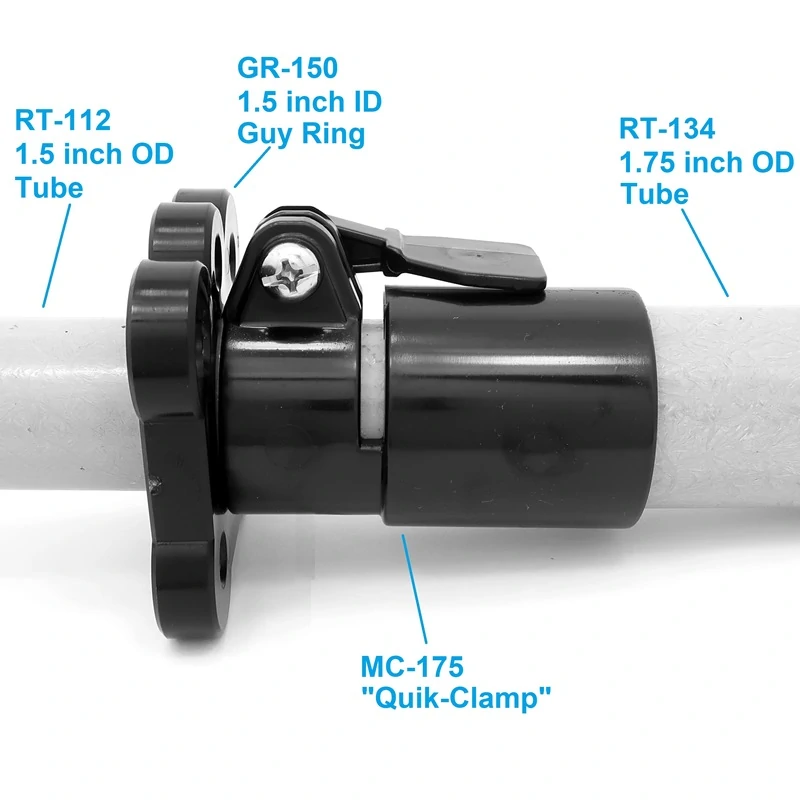

1.75 inch ID Clamp will fit on the end of our 1.75 inch OD x 1/8 WALL, Round Tube and clamp on to our 1.50 inch OD Round Tube, Part Number MC-175 (9170)

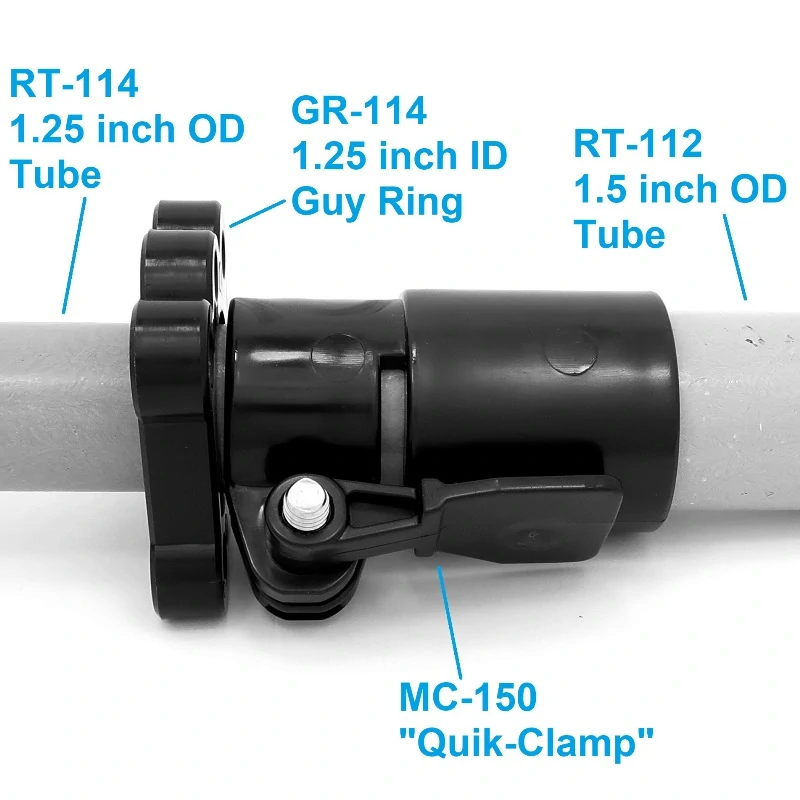

1.50 inch ID Clamp will fit on the end of our 1.50 inch OD x 1/8 WALL, Round Tube and clamp on to our 1.25 inch OD Round Tube, Part Number MC-150 (9160)

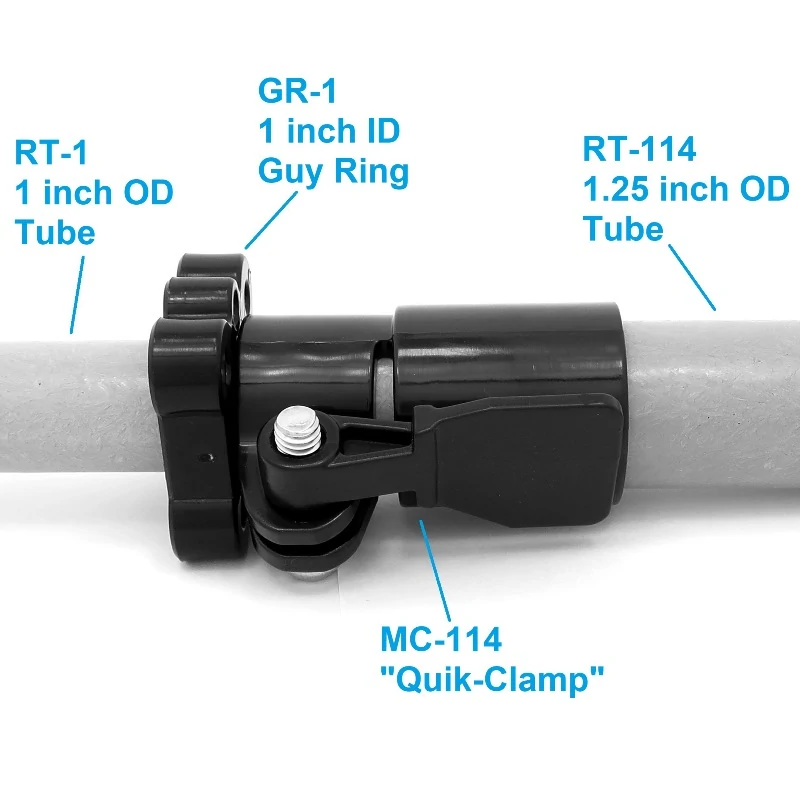

1.25 inch ID Clamp will fit on the end of our 1.25 inch OD x 1/8 WALL, Round Tube and clamp on to our 1 inch OD Round Tube, Part Number MC-114 (9150)

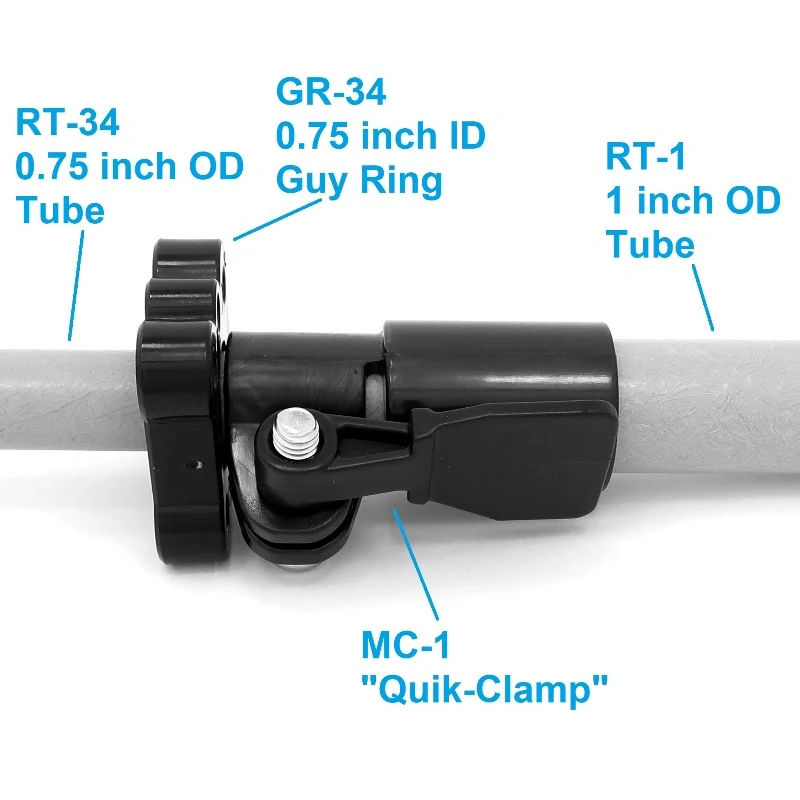

1 inch ID Clamp will fit on the end of our 1 inch OD x 1/8 WALL, Round Tube and clamp on to our 0.75 inch OD Round Tube, Part Number MC-1 (9140)

These clamps are used in our push-up masts and painter’s pole product kits.

About Max-Gain Systems, Inc.

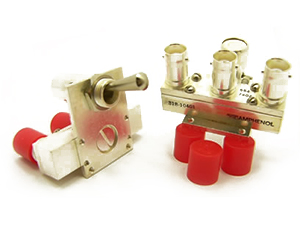

Max-Gain Systems, Inc. carries a full line of in-series, between series, right angle, T-shaped, quick connect, handie-talkie (BLACK), pigtails (coaxial jumpers), etc… RF adapters. Our RF adapter lines are constantly expanding. We keep our RF connector and adapter lines in stock. We ship both retail and wholesale quantities. To become a dealer / wholesale user, contact us with your potential usage.

Max-Gain Systems, Inc. is the number one supplier of fiberglass round hollow tube, square tube and round solid rod to the antenna manufacturing industry. We produce millions of feet a year for hundreds of different industries. This includes but certainly not limited to: marine / boating, aeronautical, agriculture, construction, emergency services, etc…. We have the unique ability to sell one piece or even a semi-truck full. Feel free to prototype using our fiberglass tube and rod then contact us for a quote on a production run. At production run quantities we can cut to your desired lengths at no additional charge. We can also perform several different fabrications (example: drilling holes in precise locations along a tube) to ensure your delivered material is ready for assembly. We have several accessory items designed for our fiberglass including but not limited to: couplers, telescoping clamps, ferrules, etc…