With thanks to radio amateurs KK5DR and VE7RF (VE7RF forwarded this information to us for inclusion on this page) , below is a method used to slow down the motors of some of the motor driven military surplus vacuum variable capacitors as removed from military antenna couplers. (On several types, voltage reduction alone will NOT yield satisfactory results).

PWM:

PWM, (Pulse-Width-Modulation), speed controller for the tuning cap motor drives. How does PWM work? A PWM converts the DC power into square-wave pulses of adjustable width. The L-C of the motor windings have a smoothing effect on these pulses.

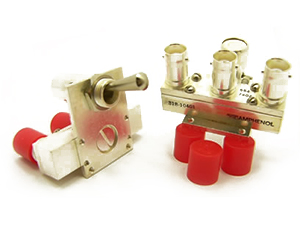

I bought this PWM motor speed control kit and built it some time back, it works nicely and drives the motors even at super slow speeds, under full torque loads. Jameco PN/ 120539CM. Below, is a photo of the PWM unit.

## Jameco makes 2 x speed controllers. PN 120539CM… and also PN 127829.

PN 127829 is imported from kitsrus http://kitsrus.com and latest specs show it’s good for 100 Vdc @ 50A The traces on the board are only good for 7.5 A

For more current [ not required for Jennings motor driven caps] the traces on the board have to be thickened up with wire.

## The kit is cheap.. $24.00 A simple DPDT, SPRING LOADED, CENTER OFF toggle is used. Up for CW… and down for CCW. The usual deal is to remove the 10 k pot from the board.. and mount it external.. [ or use a 10-20 turn precision pot]… and also use1-2 pots [ each pre-set for a different speed]… or 3+ pots and a rotary switch.

## The spring loaded toggle just reverses the polarity… to reverse the motor [ CW or CCW]

## The PWM method produces MAX torque.. even at low speeds ! [ also used on hand drills]