In this article we will be going in depth repairing a tent pole. There are many ways to accomplish this, but we will be using simple materials to repair it right. Using the right materials, and when you really need it, the tent won’t come collapsing down on you in the middle of the night. We will be making our repairs using fiberglass tube and Aluminum Ferrules.

Fiberglass Tube and Rod

We sell a wide variety of diameters and lengths of fiberglass tube and rod. From as small as 5/64″ and up to 2.5″ in outer diameters. With many sizes to choose from, you can repair almost any tent.

See a complete list of all of our fiberglass tubes and rods, here:

Preparation

To have the best success in repairing your tent pole you will need to be sure there is a fresh clean surface to attach to. If your pole is aluminum, the most common failure is a bend in the tube, and when you go to unbend it, it fails and usually makes a jagged break that just loves to eat your shock cord. If a fiberglass pole, or some other polymer pole fails, it usually ends up becoming limp in that spot as the material did not break in two pieces and it is no longer able to support weight.

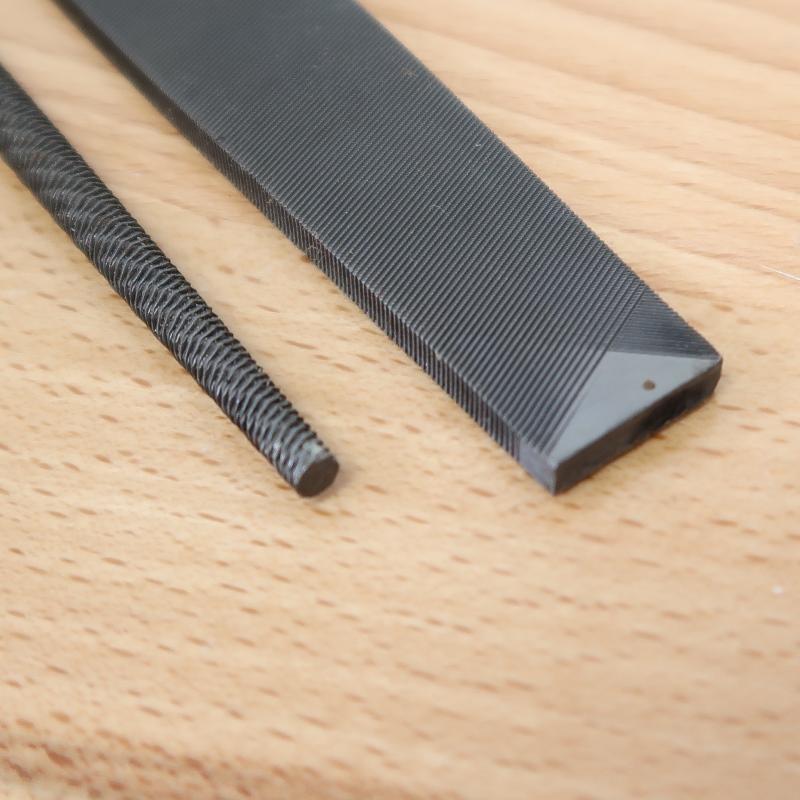

Metal pole preparation:

Be sure to use a pair of needle nose pliers to grab one end of the shock cord. Usually tied in a knot, this knot needs to be untied in order for you to remove that shock cord from the tubing. With the shock cord removed, grab the damaged pole and using a fine toothed hacksaw cut off the damaged sections of tube on both sides of the break. Using a metal file or rasp, deburr the area where you made these cuts in order to not have any sharp or rough edges that can cut your shock cord over time.

Fiberglass pole preparation:

Be sure to use a pair of needle nose pliers to grab one end of the shock cord. Usually tied in a knot, this knot needs to be untied in order for you to remove that shock cord from the tubing. With the shock cord removed, grab the damaged pole and using a fine toothed hacksaw or abrasive cutting wheel (NOT a toothed circular blade) on a mitre saw or hand saw cut off the damaged sections of tube on both sides of the break. Be sure to look closely at the “failed” tubing and make your cuts on either side of the failed, splintery, material.

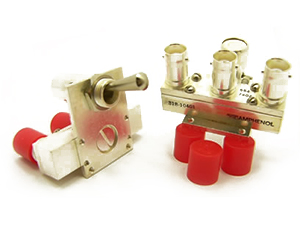

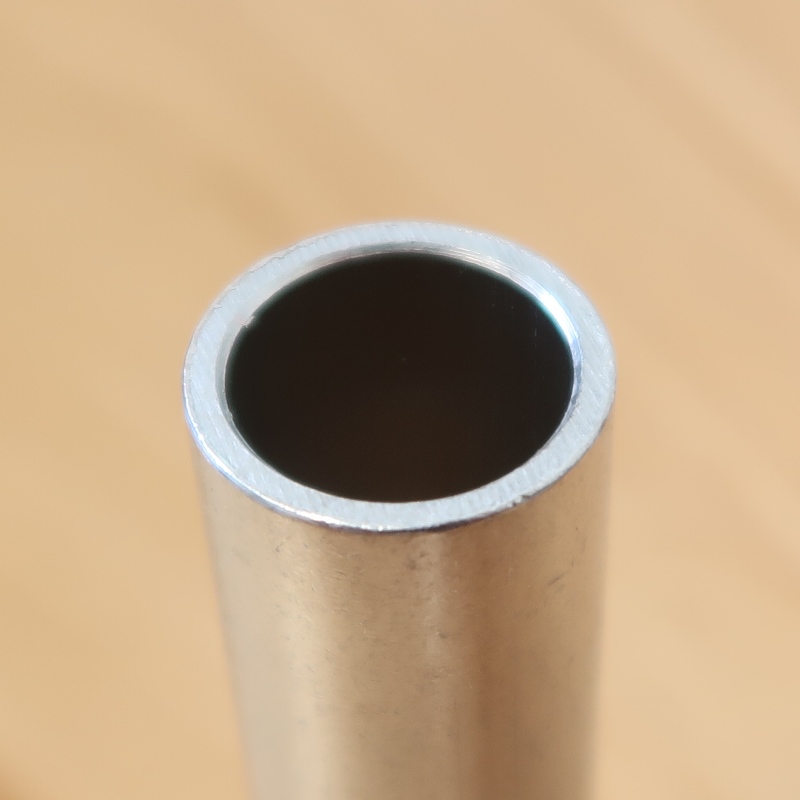

Putting in a Splice

If you are wanting to splice the pole with minimal length loss you can use only an Aluminum Ferrule to make the splice. If you had to cut out a larger section of tube you can use a close corresponding tube of the right outer diameter to the aluminum ferrule that you picked out. The Aluminum Ferrule needs to be selected based on the outer diameter of the tube you have. If your Tube does not match our outer diameters that we show for our tube, that is OK. The ferrule can still be used on a slightly smaller diameter tube. A little more adhesive will need to be used to fill the internal gap when making the final splice. Example, if your tube outer diameter is 12mm, this equals 0.472 inches. You would not want to use a smaller 3/8 inch or 0.375 inner diameter ferrule as this would not sleeve over your tube. One size up is the 0.50 inner diameter Aluminum Ferrule. In this case there would be a little bit of “wiggle room” but can easily be taken up using epoxy.

Making a longer splice may require 2x Aluminum ferrules of the correct size and single piece of fiberglass tube to match. Be sure to match the OD of the fiberglass tube to the ID the Aluminum Ferrules used. Select the fiberglass tube slightly longer than what you need. We have each piece in 5.875 inch pieces, 23.25 inch pieces, and much longer if you need. Cut the fiberglass tube to length prior to using adhesive as you will need to try to match the length as close as you can to what your tent pole was previously in order to keep the same rigidity when inserted back into the fabric.

Epoxy to use

The epoxy that works the best is the JB Weld, 2 part epoxy called “The Original Cold Weld Formula”. It comes in two tubes that you have to hand mix. You squirt out onto a piece of scrap card board 50% Hardener and 50% “steel” resin. Mix it together with a small flat head screw driver and use this to apply it onto the OUTSIDE of the tube being repaired. NEVER apply the adhesive on the inside of the ferrule directly as when the tube is inserted this will cause the epoxy to seep inside the tube making it nearly impossible to get your shock cord back through.

Fully Repaired

Once you finish using the epoxy, allow 24 hours for it to fully cure and set. Sleeve your shock cord back through and make a new knot. Your tent pole is successfully repaired.

More tips!

See more tips and tricks for fabricating fiberglass tube and rod on our “Max-Tips” page here: